| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Brand Name : Rongbao

Model Number : OEM

Certification : ISO9001

Place of Origin : Xi'an China

MOQ : 100

Price : $1-500

Payment Terms : T/T, L/C

Supply Ability : 100000

Delivery Time : 4 weeks

Packaging Details : Carton and Wood

Product Name : Aluminum Die Casting

Material : A380

Casting Weight : 0.15KG

Casting Process : Die Casting

Standards : ASTM

Dimension Tolerance : CT8

Product Introduction

NOTICE:All the products on our website indicates the ranges we can manufacture and our production capability.

We offer cast aluminum products according to customer’s drawings or samples.

Product Specification

| Dimension Tolerance | CT8 |

| Surface Roughness | Ra6.3-12 |

| Manufacture | OEM/ODM |

| Certificate | ISO9001:2015 |

| Standard | ASTM, DIN,JIS, EN, ISO, GB |

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Material | A356, A380, aluminum alloy or according to your requirements |

| Machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

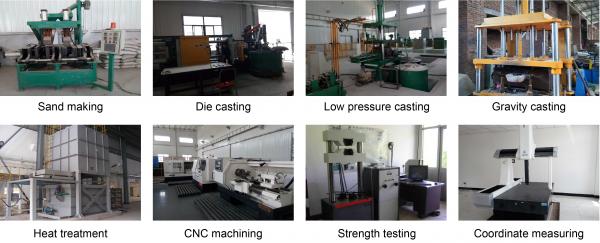

| Service | Sand casting, die casting, low pressure die casting, Gravity casting and CNC Machining |

| Testing facility | Spectrometer, Tensile test machine, Hardness test machine, CMM (Coordinate Measuring Machine) |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of aluminum casting parts |

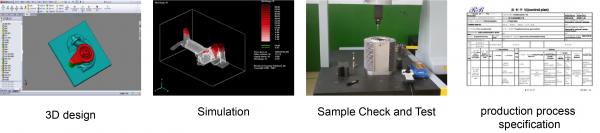

Quality Control

Casting Process

Packaging & Delivery

Our Customers

Office & Factory

Production Equipment

Raised pattern, Raised platform, Text and Pattern

These structural units are usually made into convex bodies on die castings, mainly because it is more convenient to process concave bodies on dies.

These units should be kept away from sharp corners and simple graphics and strokes.

The precision of die casting die is higher, which is basically determined by the manufacturing precision of die casting die.

Material type:

● Raw materials: alloy materials purchased from material manufacturers;

● Nozzle material: refers to the flow channel of the molding products and the rejected defective products;

● Slag discharge: refers to the material that is recycled and utilized due to the discharge of the mold design and the metal debris left in the machine and the ground in the production process;

● Scum: scum produced from the surface of the furnace during the production process;

● Secondary charge: refers to the discharge of slag and the material produced by welding of slag during production.

|

|

Manufacturer Mold Firstly / Aluminum Casting Metalwork / OEM Service Images |